How we work

SOLVING PROBLEMS

We design unique solutions for complex diagnostic problems that require expertise in a wide range of fields.

Using our staged development process, you can launch products more effectively.

KEEPING IT CLEAN AND ON TIME

Cleanliness plays a key role in microfluidics manufacturing.

We create, assemble, and package your microfluidic consumables leveraging our state-of-the-art facilities

DELIVERING QUALITY

You will get quality made in Germany that meets the demanding regulatory standards in Life Science Applications.

We support you with a quality system, tailored to the requirements of your product

SOLVING PROBLEMS

Engineering Competence

You can develop products more effectively with our experts from multiple disciplines

Complex diagnostic problems require unique solutions. To tackle your individual challenges, we build multi-disciplinary teams with our experts from

- Engineering,

- Life Sciences,

- Manufacturing and Automation,

- Tooling, and

- Quality

With this comprehensive expertise we create teams you can rely on. We can enable your next success story and build a successful long-term manufacturing partnership.

We create a balance between functionality, cost, and scalability, and we guarantee you an optimal device that meets your requirements, always keeping time-to-market at the forefront.

Solutions by competence.

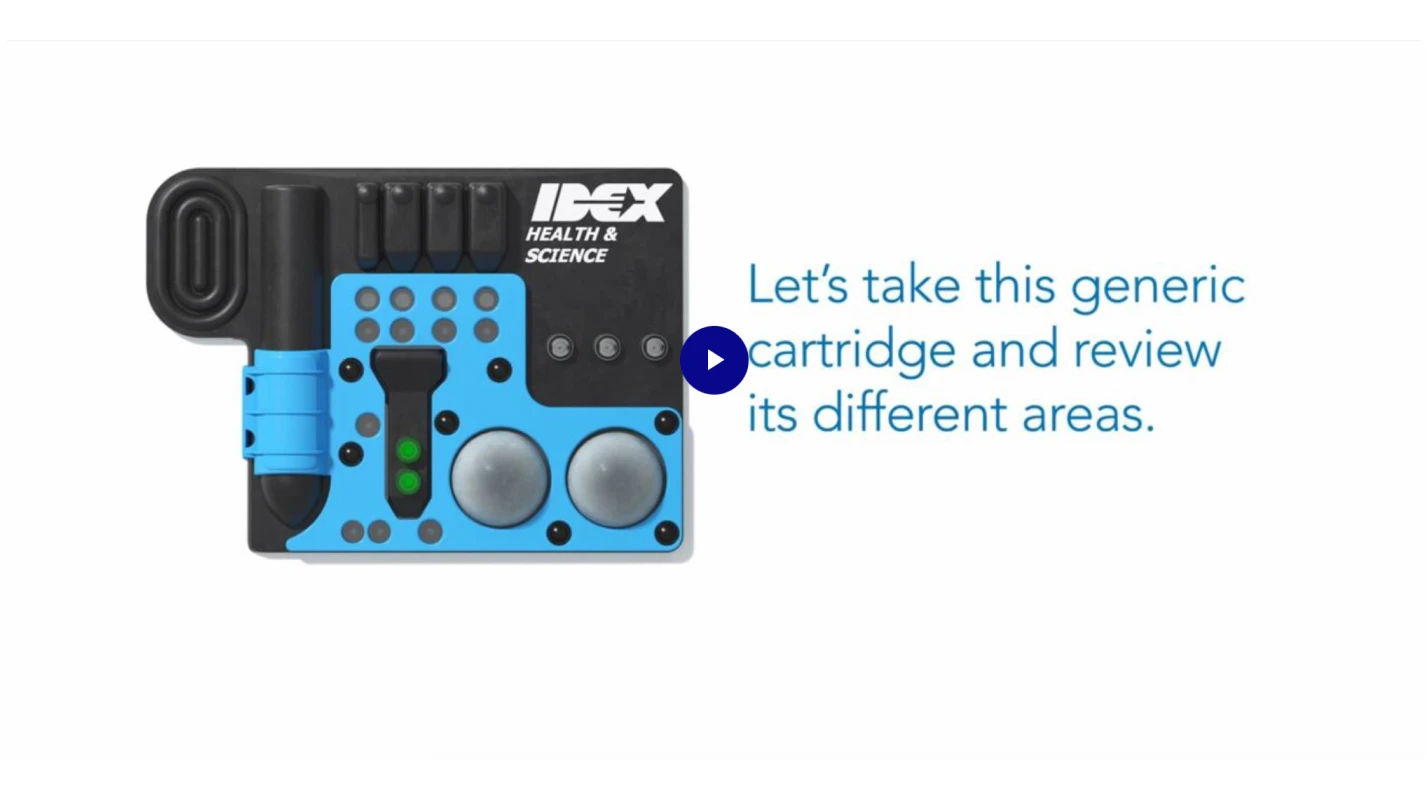

Intelligent plastic devices as well as disposable cartridges or active microfluidic systems: thinXXS offers a unique Solution Portfolio for common challenges, these include:

Dry Reagent Integration

Liquid Reagent Integration

On-Chip Valving

On-Chip Pumping

Multiplexing

Sample Handling

Our unique solutions maximize assay performance, reduce risk, and enable complete optimization of your assay workflow into a single integrated device. Please take a look at our publications to find out more:

Staged Development Process

You can launch products more effectively with our proven product development process

Using our proven process, we solve your unique problems by innovating projects through efficient product development. We simplify microfluidic product development with our disciplined process that aligns our expertise with your business objectives to take you from conception to market easier.

Whether Point of Care Testing (POCT), in-vitro diagnostics, clinical lab disposables or High Throughput Screening (HTS), we engineer and manufacture your product. The accuracy and extreme precision which we can guarantee for our microfluidic channels are crucial for many of these applications. Let’s take your challenging ideas and specifications – together we will develop the concept and design of your product.

thinXXS Microtechnology is your competent and reliable partner within each project phase: Concept Study, Design and Feasibility, as well as Ramp-up and & Manufacturing.

KEEPING IT CLEAN AND ON-TIME

Manufacturing Competence

Cleanliness plays a key role in microfluidics manufacturing.

We create, assemble, and package your microfluidic consumables leveraging our state-of-the-art facilities and clean rooms. We create a balance between functionality, cost, and scalability, and we guarantee you an optimal device that meets your requirements, with minimal time-to-market.

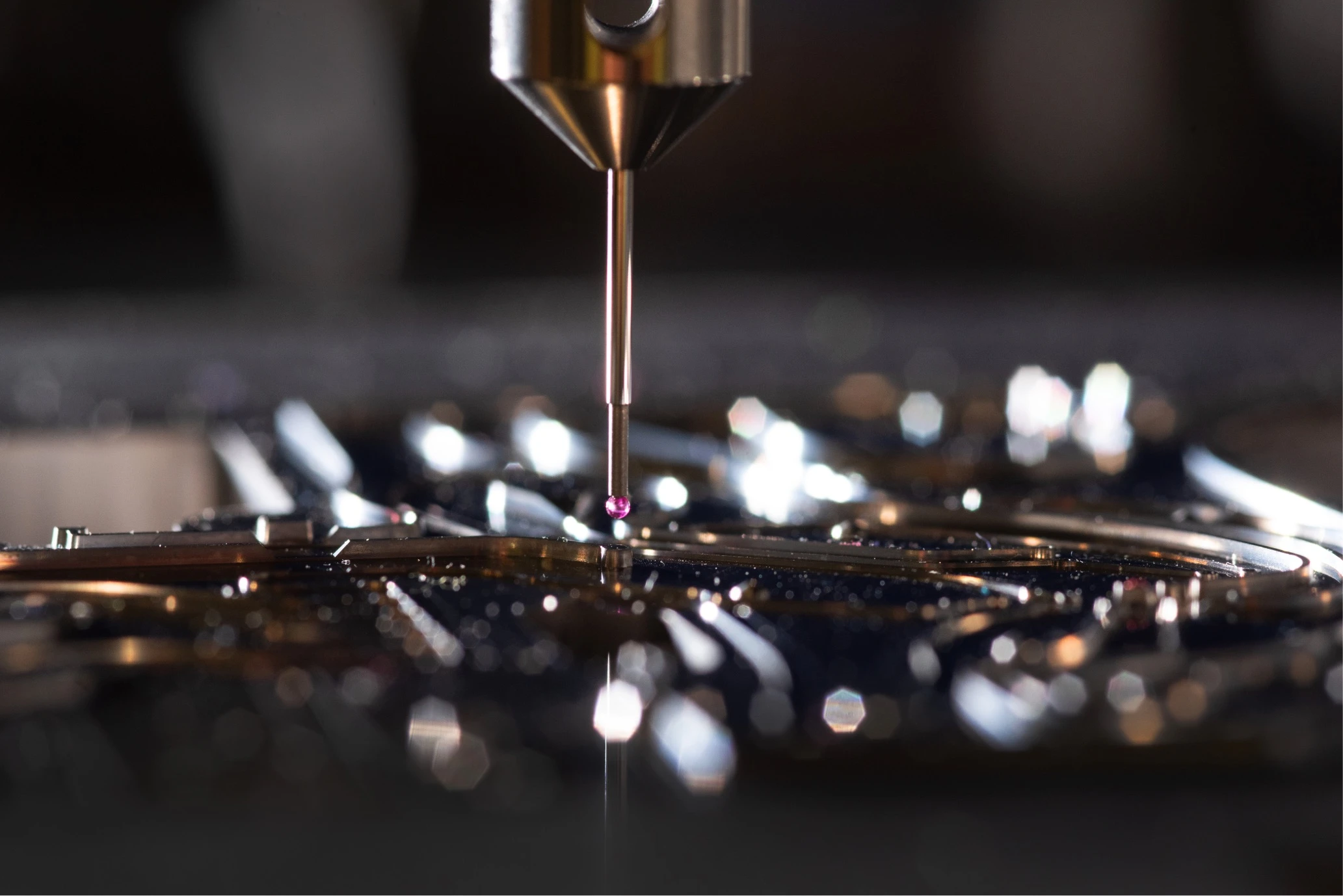

Technically challenging, injection-molded products require stable production processes for mass production. With our clean room manufacturing, we operate in a regulated, climate-controlled environment and provide documentation and component/device traceability.

From prototypes to large-scale production. Pair that with our global delivery possibilities, we are your ideal partner for microfluidic consumables, consumable components, and sample-to-answer solutions.

We manufactured millions of parts for our clients and as a full-service provider we take over responsibility to create a functional device, from production of clinical samples up to large scale production:

- Manual to fully automated assembly

- Laser-, welding- and bonding-processes

- Function tests

- Product finishing

- Dry and wet Reagent handling platform

- Packaging, and international shipping

Materials, Manufacturing, and Processes

Whether we manufacture the design we created for you or you bring us your own design, we are your OEM partner or Contract Manufacturer of choice for injection molded consumables with over 20 years of experience in:

- Precision injection molding, multi-component molding, micro injection molding

- Clean Room Manufacturing and assembly

- In-house tool design and tooling

- Ultra Precision Machining

- Automation Engineering

- Supply Chain Management

Materials include:

- A wide range of Engineering Plastics and Commodity Plastics (e.g. COC, COP, PMMA, PC, PP ...), including medical grade variants

- Thermoplastic Elastomers (TPE)

Our microfluidic consumables may combine several components made of different materials to meet the complex requirements of multifunctional microfluidic products.

Quality

Quality Control

At thinXXS you will get quality made in Germany that meet the highest requirements. Our customers from the diagnostics and life science industry operate in a regulated and global environment.

We contribute to their success through defined processes - from the initial development to serial production.

Precision requirements for microstructured parts are usually in the range of a few micrometers or below.

To guarantee highest quality, thinXXS applies high resolution measurement methods and uses the most advanced measurement equipment like:

- Scanning electron microscopy (SEM)

- Confocal microscopes

- Automated 2D/3D microscopes

- 3D Profiler

- Laser scanner

- White light- and Vertical scanning Interferometrie (WLI/VSI)

- Image processing throughout the process chain

- CAQ System for automated data acquisition

Quality Management System

Bringing microfluidic medical devices and IVD products to the market is subject to strict guidelines worldwide. Only products that are developed and manufactured in compliance with these guidelines can be successful. In order to guarantee compliance with the guidelines for our customers, we maintain a certified Quality Management System, which also includes the quality of critical suppliers.

We support our customers with a quality system, tailored to the requirements of their products. Key points are risk management support and standard-compliant documentation. We work with qualified equipment and validate our processes during the transition from prototyping to series production.

We understand the demanding regulatory requirements of our customers and we are able to guarantee the high level of quality that is required in this area. Many years of experience in working with both start-ups and globally players made us the partner of choice for all phases of your microfluidics project.

Our quality management is certified according to DIN EN ISO 13485